Automatic Sev Making Machine Manufacturers in India, Suppliers & Dealers in India

Appropriate Projects India Pvt Ltd is prominent Automatic Sev Making Machine manufacturers in India, suppliers and exporters in India, we have over 3 decades we are building the trust, our business nature is based on designing and producing efficient and hygienic machinery that helps businesses to expand their production without any difficulty. We also have the certification that is as well one of the testaments of our reliability and quality standards in the market. As a brand, we offer machines- Bhujia Making Machine in our own known brand which is synonymous with durability and technological innovations. Our machines will provide a high ROI in terms of less labor and high-volume production whether you are a small-scale entrepreneur or a large industrial unit.

What is Automatic Sev Making Machine?

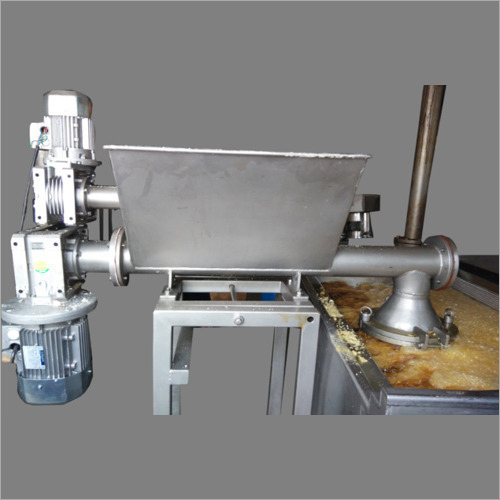

The automatic Sev making machine is a sophisticated food processing machine, which is used to squeeze and mould gram flour dough into fine, crispy strands called Sev. It automates the manual process of pressing, by maintaining the same thickness of the press and high speed of production of numerous Indian snacks like Plain Sev Making Machine.

Types of Automatic Sev Making Machine

Being as Automatic Sev Making Machine manufacturers in India, according to automation level we provided different types which are given below.

by Automation Level

- Manual Sev Machines (Hand Operated): These are turned by a handle; These are suitable in small-scale operation or at home, and lower capacity (e.g., 30-50 kg/hr) in Agra Sev Making Machine.

- Semi-Automatic Sev Machines: Motor driven, have a greater production capacity compared to manual machines e.g., 100-200 kg/hr, although These still could be fed or handled by hand as Zero Sev Making Machine.

- Fully Automatic Sev Extruders: Motor-driven, gearbox powered, extruders which are used in large scale industrial extrusion with up to 300kg/hr capacity to guarantee continuous and automated extrusion as Automatic Sev Making Machine suppliers in India.

Technical Specifications of Automatic Sev Making Machine

We've added below a specialized table of Automatic Sev Making Machine in India that provides further technical specification information.

| Specification | Manual Hand Operated | Semi-Automatic Motorized | Fully Automatic Pneumatic/PLC |

|---|---|---|---|

| Production Capacity | 10−30 kg/hr | 80−150 kg/hr | 200−500 kg/hr |

| Motor Power | N/A | 2−3 HP | 5−7.5 HP VFD Controlled |

| Operating Voltage | Manual | 220V/415V | 415V 3 Phase |

| Drive System | Gear & Handle | Belt/Chain Drive | Heavy-duty Gearbox |

| Hopper Capacity | 2−5 kg | 15−25 kg | 50−100 kg Continuous |

| Material (Body) | Cast Iron / SS 202 | SS 304 | SS 304 Food Grade |

| Pressure Type | Screw Press | Motorized Screw | Hydraulic / Pneumatic |

Sev Making Equipment manufacturers in India

We as Sev Making Equipment in India are proud of having the highly developed infrastructure in India where every machine is made with the use of products that are food grade and with the help of high-technological methods. Having experienced human resources, our products, be it our Namkeen Extruders, our fully automatic frying lines, are subjected to stringent quality tests to make sure that everything runs smoothly. In selecting us, you are entering into business with an industry leader that will appreciate customer satisfaction, ethical business transactions, and on time delivery.

Benefits of choosing us as Sev Making Plant in India

We as Automatic Sev Making Machine suppliers in India, we provided different benefits according to periods which are given below.

- High Production Efficiency: It has the ability to manufacture large amounts of sev within a short period of time; hence business is able to satisfy high market demands at a very short period of time in Thin Sev Making Machine.

- Labor Reduction: The automation reduces the use of human interventions that are very costly in labor in Automatic Sev Making Machine exporters in India and minimizes the error of human beings in Shev Making Electric Machine and for Snack Making.

- Uninterrupted Quality: The machine will provide the customers with a standard taste because every batch of sev is the same size, texture and shape in Nylon Shev and Namkeen Sev Making Machine.

- Hygienic Operation: The Automatic Sev Making Machine manufacturers in India is constructed using food-grade stainless steel and therefore, it keeps the hygiene standards high and eliminates food contamination in the food-making process.

- Economical Investment: The machine has low maintenance needs and is therefore durable, which provides long-term savings and quick payback period in Sev Extruder.

How our Automatic Sev Making Machine Works?

- Dough Preparation: Dough of gram flour is prepared and put into the feeding hopper of the machine in Automatic Sev Making Machine suppliers in India.

- Extrusion Process: An extrusion process is a powerful motor-driven force that forces the dough through a die plate.

- Shaping: The dough is shaped to the die plate holes, and it grows in the form of thin or thick strands of sev.

- Cutting: This is an incorporated cutting system that cuts the strands to the required length as These emerge out of the machine.

- Frying (Optional Integration): In fully automatic lines, the extruded sev goes through a frying system to be cooked immediately.

Applications of Automatic Sev Making Machine

We serve as Automatic Sev Making Machine exporters in India, it is applicable in different sites which are given below.

- Namkeen Manufacturing Plants: This is a commercial scale plant used to manufacture different varieties of sev including Ratlami, Nylon and Teekha sev.

- Snack Food Export Units: Assists in producing good quality and standard snacks that are able to meet the international food safety and appearance standards and be shipped internationally.

- Ready-to-Eat Food Industry: Automatic Sev Making Machine manufacturers in India is essential to businesses that package and market mixed farsan or namkeen products and are available at the retail outlets.

- Catering and Large Kitchens: These are used best in big catering services where fresh or bulk amounts of sev are needed to make snacks or to serve as a garnish.

- Hotel and Restaurant Chains: Provides central kitchens with the opportunity of ensuring a steady supply of fresh snacks in various outlets with a minimal amount of effort.

Why choose us as Sev Making Machine & Plant manufacturers in India?

- High Technology: Our machines have the current automation whereby These produce the highest output with the least wastage in Bhujia Making Plant and Nylon Sev Making Plant.

- Tailored Solutions: We offer machines that have customized capacity and area to support the production of the clients.

- Quality Assurance: Since we are TrustSeal verified manufacturer, we focus on using stainless steel of high quality and on use of materials that are reliable.

- Local Support: As a company that has its headquarters in Pune, we provide excellent after-sales support, installation and training to our clients within the local and global markets.

Appropriate Projects India Pvt Ltd is leading Automatic Sev Making Machine manufacturers in India, suppliers and exporters in India. Upgrade your snack business with the trustworthy Automatic Sev Making Machine in Appropriate Projects, Pune! Our Sev Maker are able to mix 28 years of engineering perfection with current automation to provide you high-speed, hygienic, and consistent production every day. You need less labor or more profit margins in your business, and our equipment has certification, so we are the ideal business partner. Enjoy the finest in namkeen production-to last long and made to succeed. Want to be a happy customer? Enter into an agreement with us today! By Contacting Us!

(FAQs)

High-quality and food-grade stainless steel is mostly used in construction of the machine to guarantee hygiene and a long life span.

Yes, with just the change of die plates or jalis, you can make different kinds of sev, gathiya and other extruded namkeen snacks.

We have different models of machines with a small batch configuration up to the industrial production of several hundred kilograms per hour.